How Brick Making Machine Works?

Brick making has come a long way since ancient times; it was primarily with hands, clay, water and basic fire arrangements. Then came dedicated kilns, but still most of the process was done with hands. With the technological advancements in the late 20th century and early 21st century, like everything else around the world, machines came into being. With each passing years the machines are getting better and better.

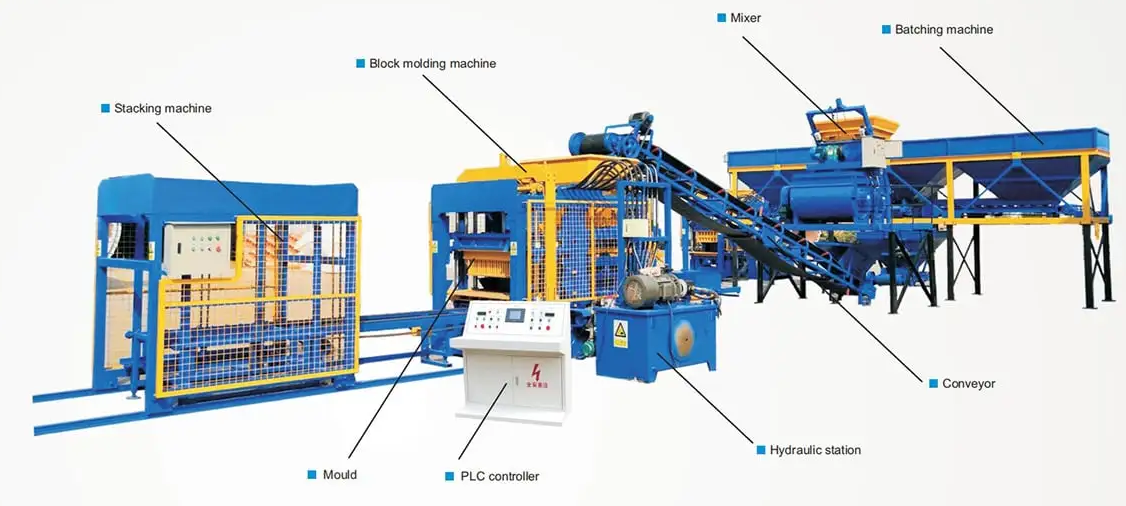

We all know the process of making bricks by hand, but have you ever wondered how brick making machine works? The process however produces the best quality bricks and blocks but the process in itself is intricate and takes care of even minutest details. Before that lets first understand the components of a brick making machine-

Brick Making Machine

The main frame consists of matching mould frame, mould and indenter. Columns make form the top and lower beams of the frame. The top and lower beams are both integrated steel castings joined by four internal columns with internal and exterior nuts to bear stress during construction. The appropriate parts are carefully toughened or forged in the critical portions. The main station consists of motor, pumps, valve block and pipes. It also has a cooling system to control the temperature of the machine. The main control system has electrical system with LED displays to monitor the process. BharatMach manufactures 2 different types of brick and block making machines:

Let us now dig deep into how each brick making machine works;

Working of a Brick Making Machine

Brick making machines are utilised when a high number of bricks must be produced in a short period of time. These bricks are heavier and stronger than hand moulded bricks, and they have a uniform shape, a finer finish, and sharp corners.

Hydraulic Pressure brick &block making machinery, the machine forms the bricks using high pressure, which might be either hydraulic or mechanical. The blended ingredients are first sent to the distributor. The ingredients are then fed into the mould box by the distributor. The ingredients are forced into the mould by the spinning teeth of the distributor. The top mould then descends, while the lower mould vibrates at the same time. In general, the bricks will be completed in 15–40 seconds. The moulding cycle is determined by the block machine models. Clients should use the automatic brick producing machine if they want to boost their working efficiency.

For a Vibro. Compaction brick &block making machinery, the brick making machine function is dependent on the mixture of material and is vibration and compression. They consist of a stacking arrangement and a hopper where they receive and store new mixture of raw material for the brick manufacture. After that, the material is dosed into the mould to fill it to the appropriate level. The tray, the mould, and the shaker are all vibrated to make it easier to fill each mould. After this, the piece is crushed to the exact size needed, and any air trapped between the sand grains and the gravel is eliminated. Finally, the machine vibrates again, and this time harder than the first time to facilitate compression, thus producing high quality bricks.

About BharatMach

BHARAT Hydraulic is a company that specialises in making industrial brick and block making machinery. Bharat Hydraulic is recognised for providing high-reliability, innovation, and cost-effective industrial machineries for all kinds of needs. They have been around for a while in the industry and with their extensive experience in the construction machineries manufacture, they have earned a global reputation. In Indian domestic market, BharatMach is one of the leading names in the manufacture and supply of brick and block making machinery. For Pavements, interlocking blocks, and building blocks, their Brick Making Machinery and Block Making Machinery create the highest quality bricks and blocks from Fly Ash, Cement/ Concrete, Lime-Gypsum, Stone Dust, River Sand, and Construction Waste materials. With their dedicated research and development vision they have their sight set on the future.

Hi! Click one of our representatives below to chat on WhatsApp or send us email to info@bharatmach.com