Brick Making Machine Manufacturer in India

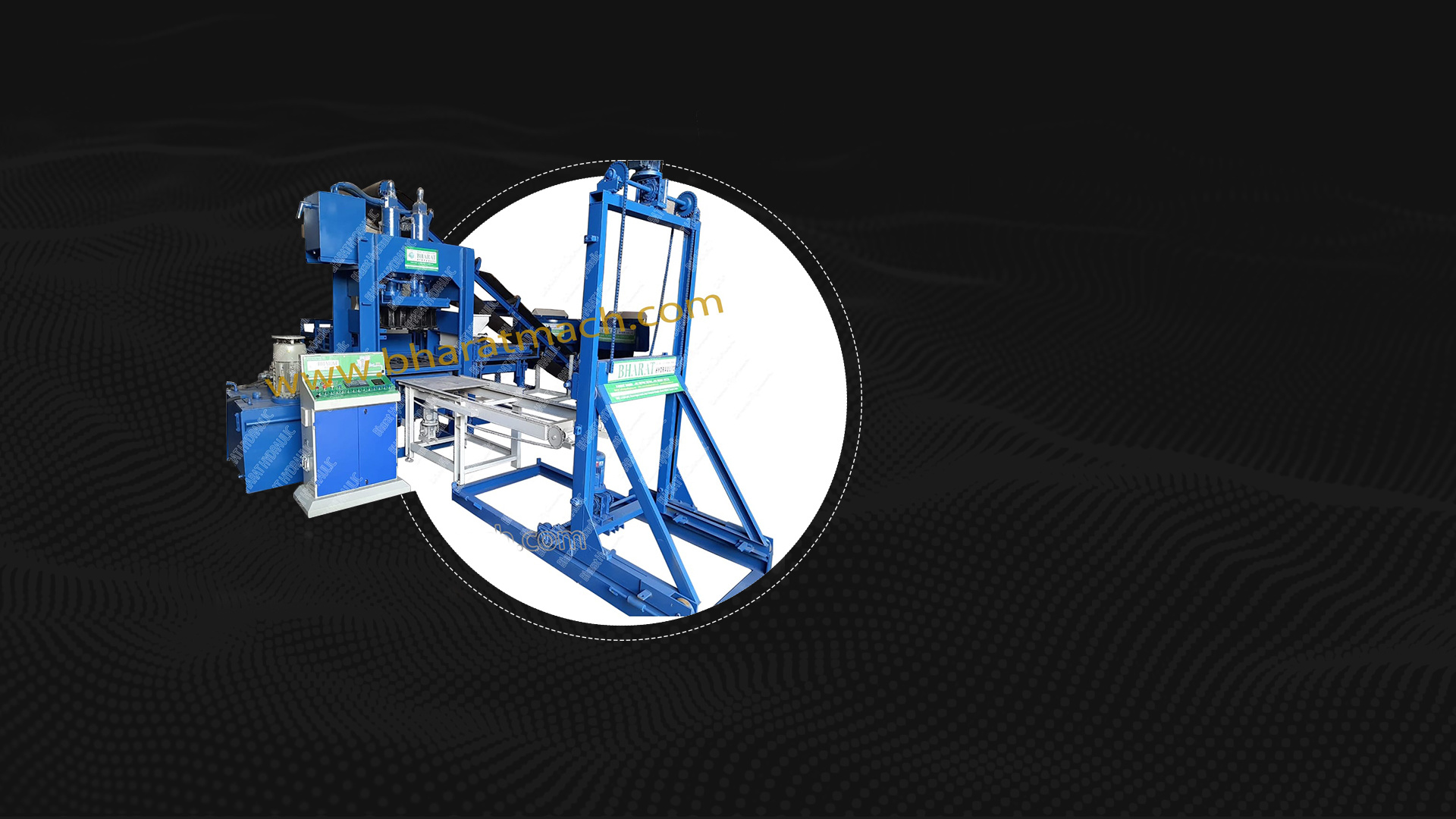

BHARAT HYDRAULIC INDUSTRIES LLP is the leading manufacturer of industrial brick and block making machinery in India. At BHARAT HYDRAULIC INDUSTRIES LLP, we use high-end and innovative production technologies to meet customers’ demand. We manufacture a wide range of machinery & equipment including, brick/block making machine, mixer machinery, material handling equipment, and rubberized PVC mould.

READ MOREOur Product Range

Our high-end technology sets us apart from our competitors. We manufacture various brick making machines, equipment, moulds, and other accessories. Our product range includes:

Brick Making Machines :

Brick Making Machines :

- Vibro. Compaction brick & block making machinery

- Hydraulic pressure brick & block making machinery

- Designer tiles / paving block making machinery

- Mixer machinery

- Material handling equipment

- Brick & block die

- Hardener chemical

- Recycle ply pallets sheets

- Rubberized PVC mould

- Plastic paver / tiles mould

Nature of Business

Manufacturer & Exporters

Total Number of Employees

25 to 50

Year of Establishment

2008

Annual Turnover

Rs. 5 - 10 Crore

IEC Number

24169161

GST No.

24AAYFB0047J1ZB

Videos Of Our Brick Making Machinery Products

BHA-102C Automatic Multi Purpose Brick And Block Making Machine Plant

BHA-102E Mini Automatic Multi-purpose Bricks & Block Machine with Vibro. 6cvt

BHS-603B Vibrating Table Plant / Designer Tiles/Paving Block making Machine

Why Choose Our Block Making Machinery Products?

24/7 Online Support

Same day parts dispatch facility (working day).

Standard make parts so easily available in market.

Serviceman/Engineers available within 2 to 3 working days.

100% Surety of quality products.

PRE-SALES SERVICES

Professional and comprehensive pre-sales service guides and directs your investment.

ON-SALES SERVICES

We work on the details of the contract with the customers so that there is no uncertainty.

AFTER-SALES SERVICES

Bricks product advice service , 24 hours customer service , Free machine operation and management training , 1 year spare part guarantee.

WHAT OUR CLIENTS SAY

BHARAT HYDRAULIC INDUSTRIES LLP has become the best selling Hydraulic Machine recently. Just read our actual customer reviews to understand the reason.

Great service. They really helped us out when our machine panel went out. They made the service and payment very convenient for us. We highly recommend this company.

We purchased a machines from BHARAT HYDRAULIC INDUSTRIES LLP and their service and applications team installed and trained us like it was a new machine. Years later they always respond in a timely manner and treat us like we bought a more machines from them.

We love our new heaters. We should have done this years ago. The installation was done professionally and in the time frame allotted. It was a great experience.

MEMBERSHIP & AFFILIATIONS