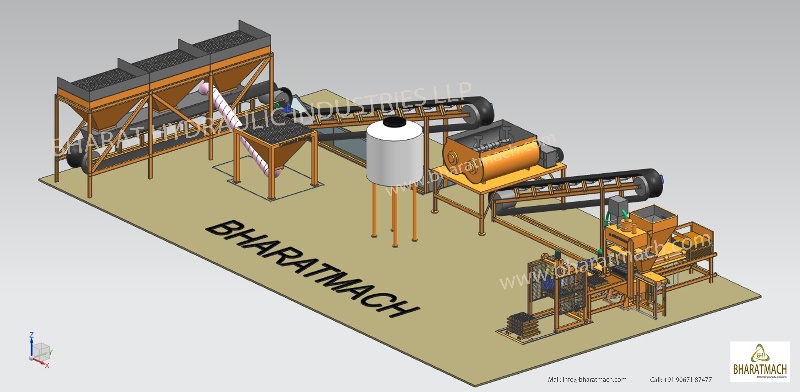

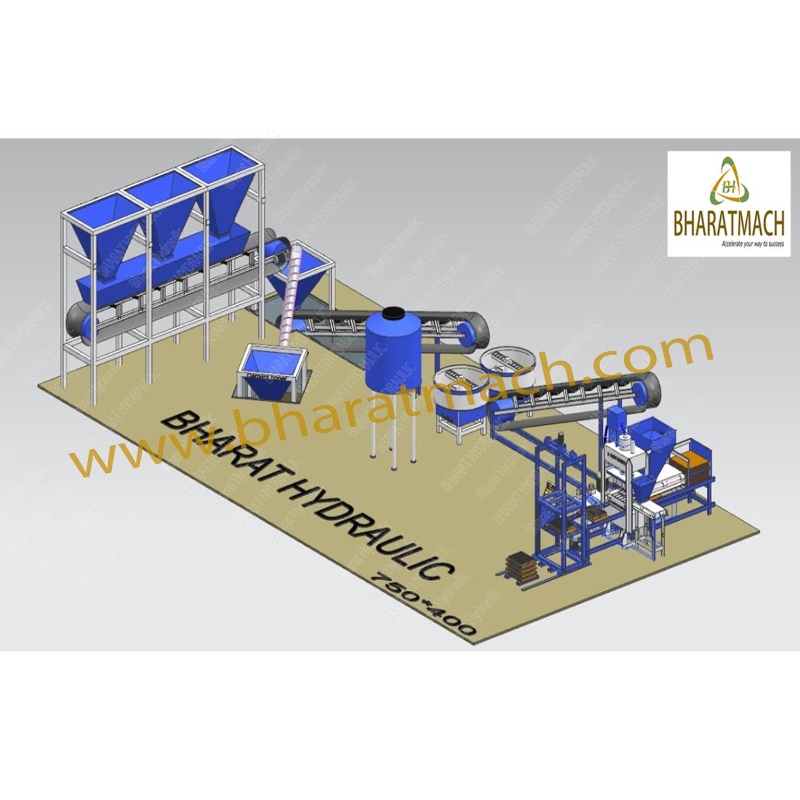

BHF-200 Fully Automatic Vibrotech Multi Bricks & Bock Machine With Batching series

Vibro. compaction: As the particles are pressed to closer, the vibration will excite all the particles so that they shuffle into place together. As the particles vibrate, the volume is reduced; this compaction is more uniform from outside inward from all the surface, not just the top. Vibration greatly assists in compaction but also helps to speed up the compaction process. The increase in brick-making results in a faster daily target achievements. More connection allow for better cohesion & adhesive forces when de-moulding. Typically, even without a chemical agent added, brick formations will hold together from the moisture content alone. This shows how well the brick will be bonded when cement is added. Cement in the water will create micro-joins between the particles at the connection points (following the water lattice structure present). Thus when more connections can be made, the stronger the bond will be; additionally this means less void space and therefore less wasted cement to fill the spaces.

Electricity Require: 95 Hp / 70.84kW (Three-phase)

Pressure &

Vibration: 40 to 50 Tones & Vibration 12.5Hp + 12.5Hp.

Oil Tank capacity: 750ltrs. Oil tank capacity with Oil cooling system

Brand/Make: BHARATMACH / Bharat Hydraulic

Model/Type: BHF-200 (24cvt.)

Main Tech.: 40 to 50 Tones pressure with Vibration, Auto. Double feeder, Sensor system & PLC based Panel Board.

Fully Automatic Vibrotech Multi Bricks & Block Making Machine with Batching series

Hi! Click one of our representatives below to chat on WhatsApp or send us email to info@bharatmach.com